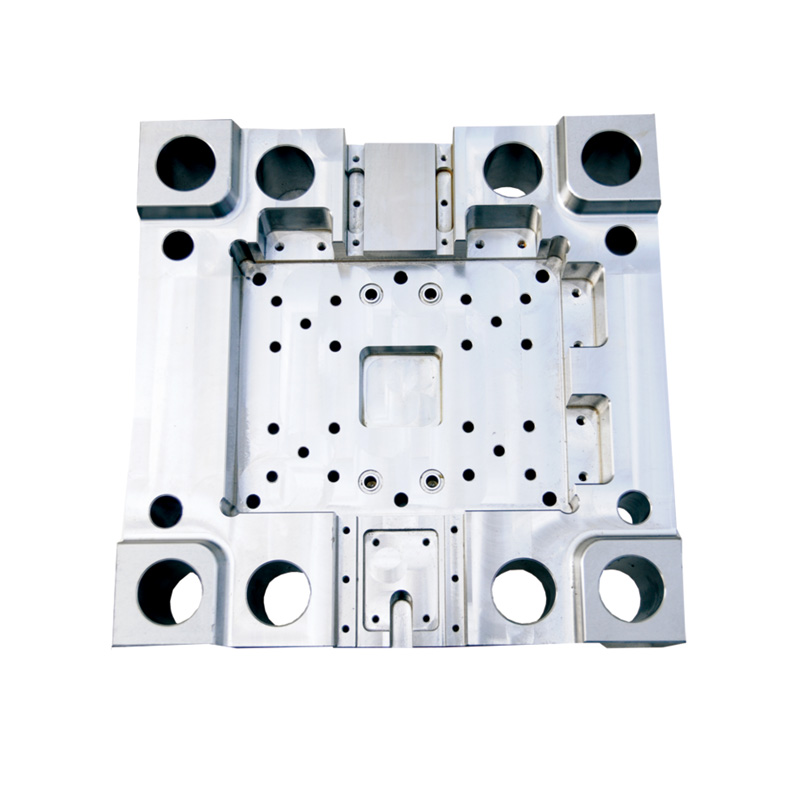

The injection mold base is the basic support structure of the entire set of injection molds. Its main feature is to provide an installation reference for the core components of the mold, withstand the strong clamping force during the injection molding process, and ensure that the mold remains stable under high pressure and high temperature working environment. The mold base must have sufficient rigidity, overall strength and dimensional stability.

If the injection mold base is deformed, it will directly affect the overall accuracy of the mold. This deformation may be caused by insufficient structural strength in the design stage, improper residual stress release in the manufacturing process, or mechanical damage caused by overload use, improper operation or lack of maintenance in long-term production. The deformation of the base will destroy the original precise matching relationship between the mold templates.

The destruction of this matching relationship will cause the core mold closing action to fail to achieve the preset precise closing state. The direct consequence of this is the uneven gap between the mold parting surface or the key matching surface. During the injection molding process, the molten plastic is very easy to penetrate these abnormal gaps under high pressure drive. After the plastic cools and solidifies, irregular and redundant plastic thin edges that exceed the original design outline are formed at the corresponding position of the product, that is, the product burrs.

The deformation of injection mold base is one of the important factors that lead to the deterioration of mold precision. The problem of loose mold closure caused by it is closely related to the burr defect of injection molded products.